Sub: Concrete block – Understanding the Building Unit Behind Modern Masonry

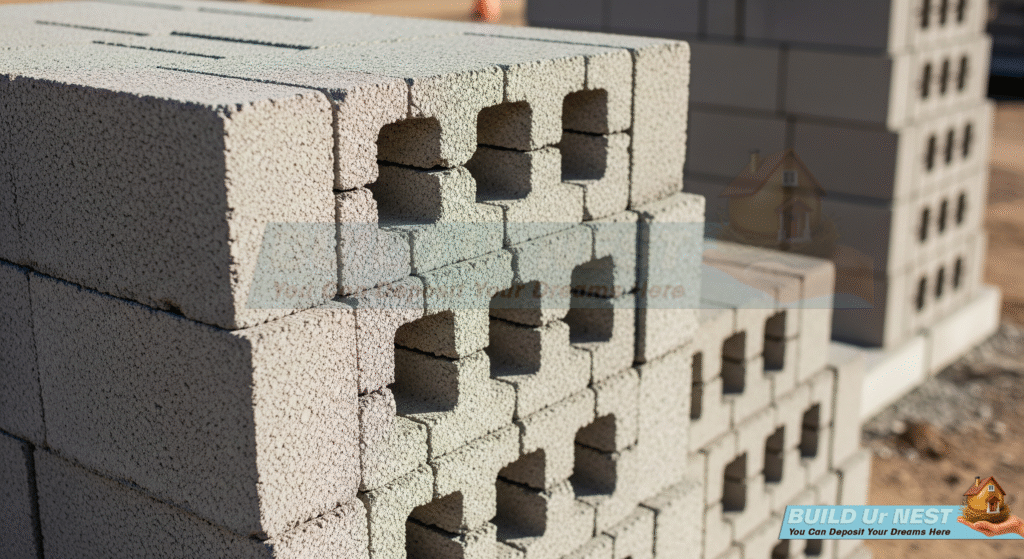

A concrete block, also known as a cinder block (US), breeze block (UK), or concrete masonry unit (CMU), is a key element in the world of construction. Its uniform size, strength, and adaptability make it an essential component in both residential and commercial building projects. From traditional walls to decorative facades, these blocks have proven their value in durability and design.

Thank you for reading this post, don't forget to subscribe!

What is a Concrete Block ?

A concrete block is a standard-sized rectangular building unit made from a mixture of cement, aggregates (like sand or gravel), and water. These blocks are often created with hollow cores to:

Reduce weight

Improve insulation

Provide channels for pouring concrete or reinforcing steel

Their modular shape allows builders to construct walls in the traditional masonry style, stacking them in staggered rows with mortar in between.

Global Naming Conventions

Concrete blocks go by different names across the world:

Cinder blocks – U.S. term when fly ash or bottom ash is used as aggregate.

Breeze blocks – U.K. term derived from “breeze” (coal ash dust).

Besser blocks – Australian term after the Besser Company machines.

Clinker blocks – Use industrial waste like slag or clinker (mineral impurities).

These variations often reflect regional building styles and materials, but all share the same core functionality.

Composition & Sustainable Innovations

Most concrete blocks are made from cast concrete, using materials such as:

Portland cement

Sand and fine gravel

Fly ash, bottom ash, slag cement

Recycled glass or aggregate

Lava rock (for color and lightness)

Eco-conscious builders increasingly prefer recycled materials, not only to reduce environmental impact but also to qualify for LEED certification through sustainable building practices. In Europe and colder regions, autoclaved aerated concrete (AAC) is used for its lightweight and thermal insulation benefits.

Sizes and Structural Efficiency

Concrete blocks come in several standard modular sizes:

U.S.: Nominal 16 x 8 inches (actual size slightly less to allow mortar gaps)

U.K./Ireland: 440 × 215 × 100 mm

Australia/NZ/Canada: 390 × 190 × 190 mm

Most blocks are designed with two or more cores, which allow:

Mortar grip and handling ease

Reinforcement with steel rods (rebar)

Filling with foam for added insulation

Special shapes like U-shaped lintel blocks, jamb blocks, and bullnose corner units enable precise construction for doors, windows, and design features.

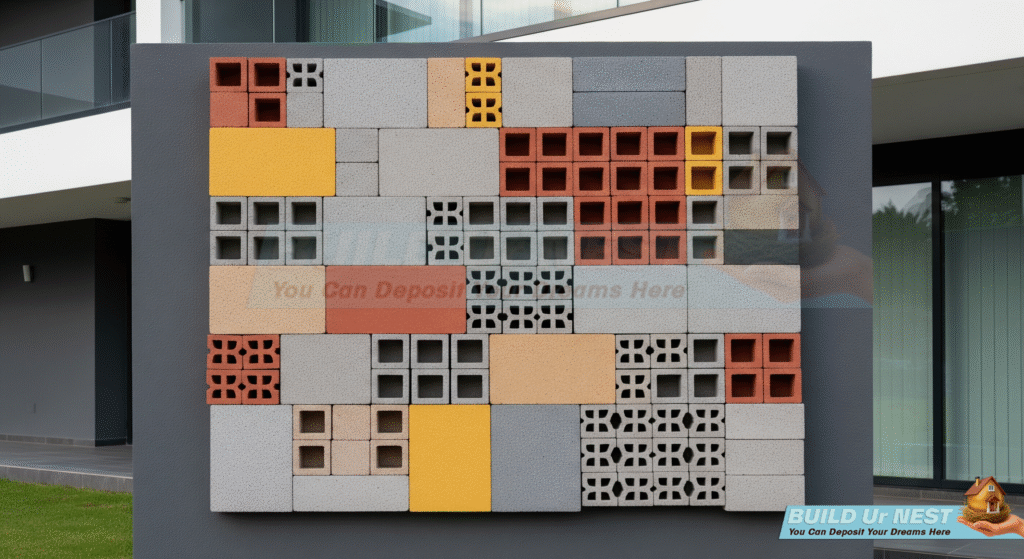

Aesthetic & Functional Variety

Beyond basic structure, concrete blocks can also offer decorative finishes, like:

Split-face or split-rib textures

Colorful aggregates (lava rock or glass)

Scored joints to mimic smaller bricks

Ventilated breeze blocks for airflow and light

These finishes have made concrete blocks popular not just for foundation work, but also for facades, garden walls, and modernist architecture.

Conclusion: The Backbone of Modern Masonry

From skyscrapers to backyard patios, concrete blocks are the unsung heroes of construction. Their strength, versatility, and design options make them a timeless solution in both structural and aesthetic applications. As sustainability and efficiency continue to drive innovation in building materials, concrete block processing remains at the forefront of architectural evolution.

Build smart. Build strong. Build with concrete blocks.